Over the last few years, winter months have been getting longer while summers have been getting warmer.

As a consequence, there is now more awareness about the importance of thermal insulation for our homes.

The first thing to take in consideration is the efficiency of our windows as the insulation of the frame has an enormous impact on their performance.

The reduction of energy consumption has become an important concept, involving many different sectors, including the window furnishing industry where lower levels of thermal transmittance are always required.

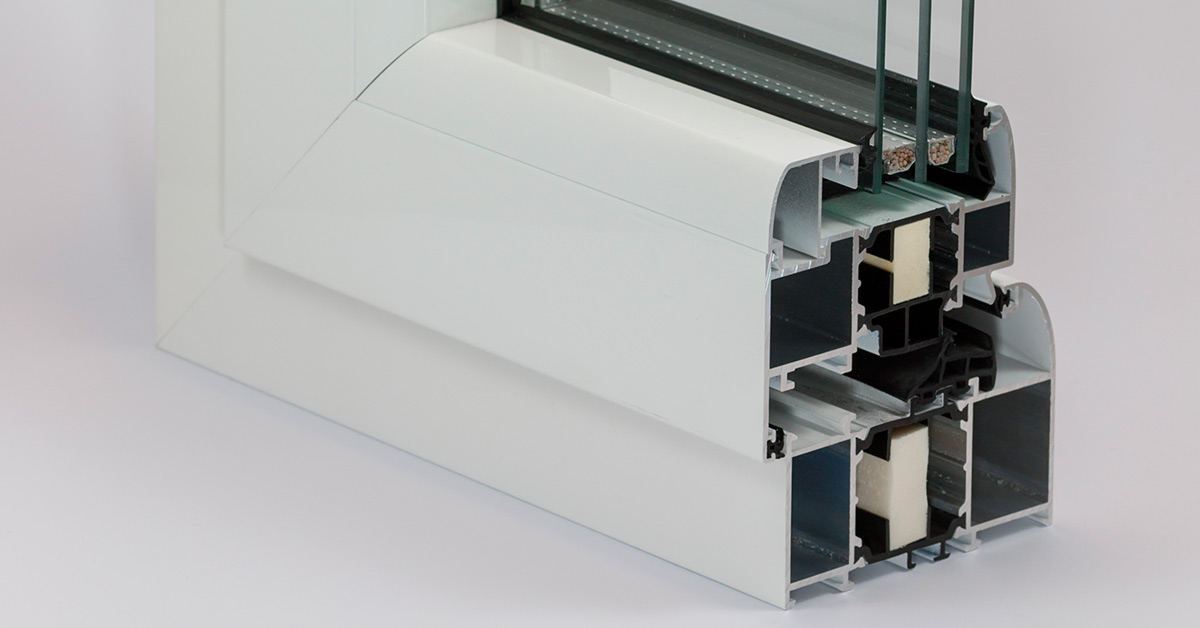

As we already saw in one of our previous articles, the insulation inside a window frame can be achieved thanks to thermal break aluminium windows which are designed with two bars in thermoplastic.

By breaking the continuity of the structure, this particular plastic material, will obstruct the thermal bridge, typically made of aluminium, and will reduce thermal dispersion.

There is no need to use this system with PVC and wooden windows as they are already high insulating materials.

A new generation of spacers, used for insulating windows, defined as “thermal break” or “warm edge” have also been helping towards the target of reducing energy consumption.

Warm edge spacers: what are they?

When our home offers a comfortable temperature, we can enjoy all the benefits of thermal wellbeing and living comfort.

It’s thanks to warm edge spacers that we can appreciate all these benefits.

Spacers designed with materials capable of improving insulation performances are called “warm edges“ as they reduce the thermal bridge created at the base of the glass by conducting elements such as aluminium, a material very often used to produce spacers for double glazing.

There are many types of warm edge spacers like flexible foams, thermoplastic, combined plastic and metal materials, and stainless steel, however, to choose the right one it’s necessary to take in consideration a few elements: environment, construction processes, regulations and energy.

Warm edge spacers available in the market

As of today, warm edge spacers can be divided into three groups:

1. Flexible spacers: malleable and flexible materials, with thermoplastic base and/or silicon

2. Combined spacers made of plastic and metal

3. Stainless steel spacers

Purchasing windows with warm edge spacers will reduce thermal transmission and consequently, diminish energy consumption costs and carbon emissions.

Functions of warm edge spacers

A warm edge spacer can offer high performance and help in many of the regular duties of a window:

- soften the stress caused by the thermal expansion and change of pressure

provide a barrier against humidity

provide an insulating barrier, reducing the formation of internal condensation

allowing better performances and improved energy efficiency, especially in the winter months but also during the summer.

Double glazing and warm edge spacers

Double glazing was designed by assembling two glasses through aluminium spacers.

After new technological developments and to improve the performance of thermal insulation, aluminium was eventually replaced by the more performing warm edge spacers as this material used to create so-called thermal bridges which are essentially points where energy gets dispersed.

Thanks to this solution, double glazing fitted with internal blinds, in addition to providing many levels of solar shielding and the maximum levels of privacy, they also offer high energy savings.

As we saw, the best solution to get the best energy saving is to opt for windows designed with warm edge spacers, choosing the most suitable to your needs.